Neodymium magnets (also known as "NdFeB", "Neo", or "NIB" magnets) are permanent magnets made of neodymium, iron, and boron. They belong to the rare earth permanent magnet system column and have the highest magnetic properties of all permanent magnets, stronger than ferrite, samarium cobalt (SmCo), and aluminum nickel cobalt.

In addition to high-strength magnetic force, cost-effective, become the majority of consumers, commercial, industrial and technical applications of the best choice. Neodymium magnets (NdFeB) provide maximum performance with minimal magnet volume. A coating is applied during processing to prevent corrosion risk - NiCuNi, zinc, epoxy and gold are popular finishes.

Used in almost every industry: mining, automotive, aerospace, wind, military, appliances, lighting, electronics, separation, motor and generator industries Just to name a few.

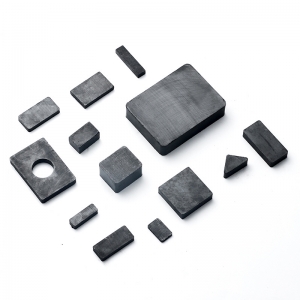

Ndfeb magnet common shape

Our neodymium magnets meet REACH and ROHS standards. They do not contain any SVHC, and neodymium is produced according to ISO9001 quality control standards. NdFeB neodymium magnets are typically available as stock and custom products in block, disc, ring, arc, sphere, triangle, trapezoid, square punch, round punch and many other shapes.

Neodymium magnet is the most suitable temperature

The properties of neodymium magnets are affected by temperature. As temperatures get lower, neodymium magnets get stronger and work even better at lower temperatures. Neodymium magnets are said to work at temperatures as low as -130°C. It is also possible for some grades of neodymium magnets to be exposed to very high temperatures before they begin to change their properties, and to temporarily or permanently, lose their magnetism.