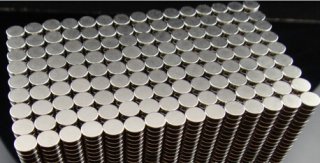

Strong Disc Neodymium Small Magnets

Most disc magnets have their north and south pole on the flat circular surface (axial magnetization). The few exceptions, which are diametrically magnetized, are specifically marked. The combination neodymium-iron-boron is currently the strongest available magnet material worldwide. Even with small areas the neodymium disc magnets achieve remarkable holding power, which makes them very versatile.

Application: Neodymium(NdFeB) Magnet are widely used in many fields, such as motors, sensors, microphones, wind turbines, wind generators, printer, switchboard, packing box , loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, ect.

Material: Sintered Neodymium-Iron-Boron (NdFeB)

Size: 2mm x 12mm. Many Existing Moulds, can be customized according to customer's need.

Direction of magnetisation: Thickness Magnetized, Axially Magnetized, Diametrally Magnetized, Multi-poles magnetized, Radial Magnetized.

Performance: N35 N38 N40 N42 N45 N48 N50 N52...

Shape: Customized (block,disc,Cylinder, Bar, Ring,Countersunk, Segment, hook, cup, Trapezoid, Irregular shapes ,etc)

Coating: Nickel, Zinc, Chromium, Epoxy, Gold, Silver, Parylene, Everlube, Passivation, Copper, Chemical, PTFE and more.

Neodymium magnets are a composition of mostly Neodymium, Iron and Boron. If left exposed to the elements, the iron in the magnet will rust. To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated. There are a variety of options for coatings, but nickel is the most common and usually preferred. Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes our magnets much more durable than the more common single nickel plated magnets. Some other options for coating are zinc, tin, copper, epoxy, silver and gold. Our gold plated magnets are actually quadruple plated with nickel, copper, nickel and a top coating of gold.

Size tolerance: +/-0.05mm for diamater /thickness, +/-0.1mm for width/ length

Max Working Temperature: 80-220 Celsius or Customized

We accept customized services: 1) Shape and Dimension Requirements; 2) Material and coating requirements; 3) Processing according to design drawings; 4)Requirements for Magnetization Direction; 5) Magnet Grade Requirements; 6) Surface treatment requirements (plating requirements)

About US

Fuzhou AOMAG Magnetics Co.,Ltd. have been dedicated to being "your magnet solution source". As a professional Largest magnet manufacturer, magnets supplier and OEM magnet exporter, AOMAG was established in 1996 and specialized in R&D, production and sales of rare earth magnets, permanent magnets, (licensed patent) neodymium magnets, Sintered NdFeB magnets (Neodymium-Ferrite-Boron) , strong magnets, Radial Ring magnets, bonded ndfeb magnets, ferrite magnets, alnico magnets, Smco magnets, rubber magnets, injection magnets, magnetic assemblies etc. Our factory has over 28 years' manufacturing experience in making magnets with different shapes, different coating, different magnetized direction, etc. Our annual design output is over 6000Ton, currently, actualy output is around 3000Ton ,of which around 60% is for export market especially for West Euro, North America, Korea, Iran, India, etc. We implement ISO 9000 idea in the factory over 7 years to keep steady quality level.

Our Services

In order to quote you the best price quickly. please provide the following information:

1. Magnet grade, size,coating etc.

2. Order quantity.

3. Attached the drawing if customized.

4. Any special packing or other requirements.

Export Advantage:

1. All inquiries, questions and emails will be replied within 24 hours.

2. Samples and small quantity are available.

3. Stock material for stable production.

4. Most favorable Price is available.

5. Quick delivery time & precise size tolerance.

8. Good quality and assured service.