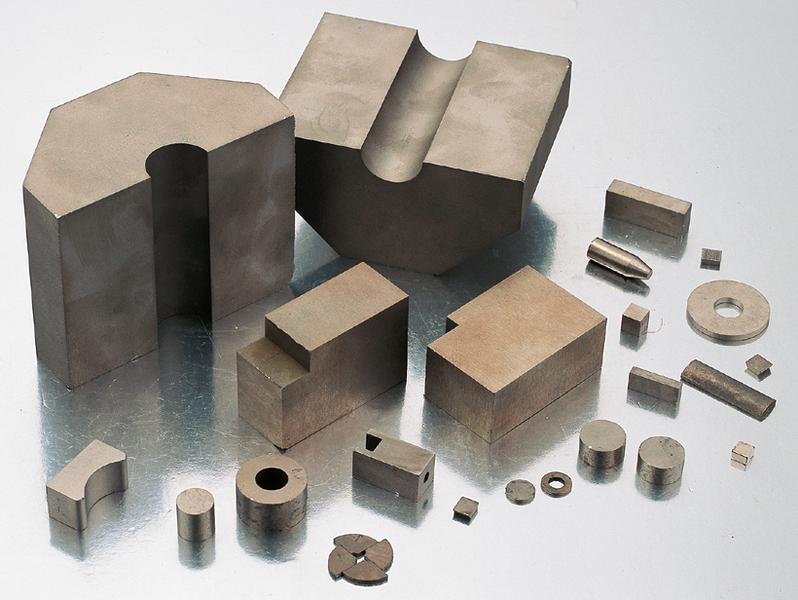

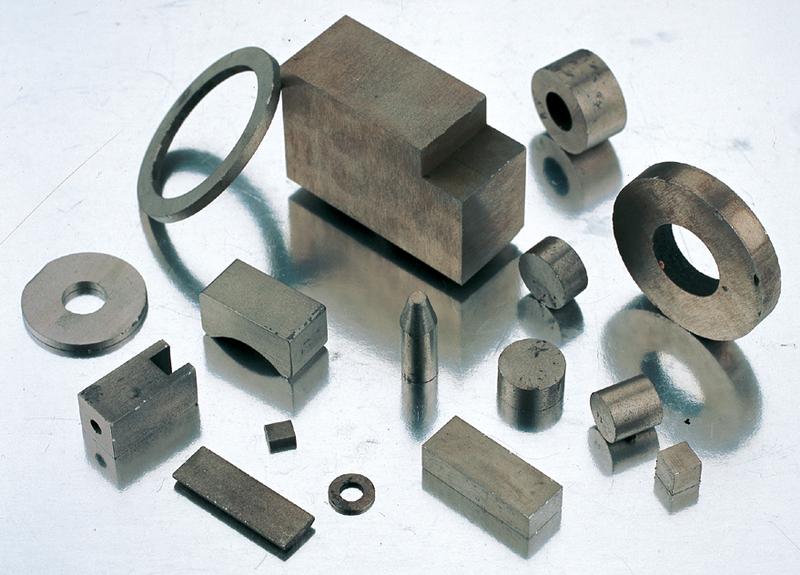

Samarium Cobalt (SmCo) magnet is a high performance, low temperature coefficient permanent magnet, which made of samarium, cobalt and other rare earth elements. The biggest advantage is its high working temperature, the maximum working temperature is up to 300℃. It doesn't need to be coated because it is difficult to be eroded and oxidized. Samarium Cobalt magnet is widely used in motor, sensor, meter, electronic, watch, automobile, aviation and other applications. There are two alloy series for SmCo magnets: SmCo5 and Sm2Co17(Magnetic Properties of Sintered SmCo Magnets).

Magnetizing and Handling

Samarium Cobalt magnets are very brittle and very strong magnetically. Therefore, it is crucial to handle these magnets with extreme care to avoid personal injury and damage to the magnets. Fingers can be severely pinched between attracting magnets. Magnets can chip if allowed to “jump at†an attracting object. It is highly recommended that when constructing rare earth magnetic assemblies, they be magnetized after assembly.

Samarium Cobalt Machining

Since Samarium Cobalt magnet material is prone to chipping and cracking, it does not lend itself to conventional machining methods. It can, however, be abrasively ground, but only with the use of liberal amounts of coolant. The coolant minimizes heat fracturing and the risk of fires caused by oxidized grinding dust.

Applications of Samarium Cobalt Magnets

Computer disc drives

sensors

traveling wave tubes

linear actuators

satellite systems

motors where temporary stability is vital.

Tolerances

For as pressed material, tolerance on the thickness (direction of magnetization) is ± .005. Other dimensions are ± 2.5% or ± .010, whichever is greater.According to IMA standards, visual imperfections such as hairline cracks, porosity and minor chips are commonly found in sintered metallic magnets. A chipped edge is considered acceptable if no more than 10% of the surface is missing. Cracks are acceptable as long as they do not extend across more than 50% of pole surface.