Bonded NdFeB Magnets

Bonded Neodymium magnets are manufactured through the compression process. This process involves mixing neodymium powder with epoxy as a binder and pressing it into a die cavity with no magnetic field, thus making these magnets Isotropic. Pressed parts are then placed into the oven for curing. Compression bonded neodymium magnets are an excellent choice over other magnet types (sintered neodymium, sintered samarium cobalt, and hard ferrites) that have limits to some shapes that compression bonded magnets do not have. With their high energy product reaching up to 12 MGOe it makes them ideal for many applications requiring high magnetic strength and tight tolerances. Since no magnetic field is applied during the compression the finished product can be magnetized in any direction. Having epoxy as a binder in the manufacturing process for compression bonded magnets makes the magnets resistant to most industrial automotive fluids. With relative low tooling cost and quick turnaround compression bonded neodymium magnets are the choice for a wide variety of applications. The final product can be epoxy coated for durability and more resistant to corrosion.

1. Professional neodymium magnet manufacturer over 28 years.

2. Good price and high quality with REACH, ROHS Certificate,etc.

3. Long-term stability of magnetic properties.

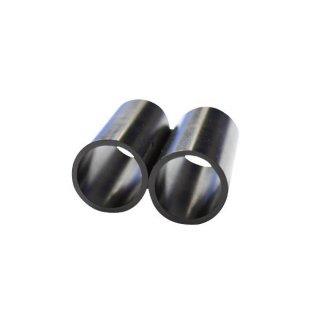

Bonded Neodymium Ring Magnet Features:

1. High precision;

2. Excellent magnetic properties;

3. Stable working temperature;

4. Good corrosion-resistance and nice surface.

Bonded magnet can be produced in different shapes, sizes and grades depending on the end use application. Bonded magnet offers numerous benefits over other magnet technologies including higher coercivity BH max, wider tolerance on tolerances, increased design freedom, ease of handling during assembly operations, reduced weight compared to traditional magnetic components such as blocks or rings, ability to be shaped/molded into complex geometries with intricate surface patterns for improved functionality and it can be combined with bonded magnets in a single product.

Bonded magnet is a kind of composite magnet which has the characteristics of both permanent magnet and binder material. Mainly used in office automation equipment, electrical machinery, audio-visual equipment, instrumentation, small motors and measuring machinery, mobile phones, CD-ROM, DVD-ROM drive motors, hard disk spindle motors HDD, other micro DC motors and automation instruments fields.

Different Types Magnets are Available

Custom Neodymium Magnets – We can also custom manufacturer neodymium block magnets to your exact specifications, just send us a special request and we'll help you determine the most cost effective solution for your project. AOMAG has near 20 years of experience in manufacturing complex magnetic assemblies for more technical applications