About Bonded NdFeB Magnet

Generally, the bonded NdFeB magnet is produced by molding compression of the compound NdFeB alloy powder with epoxy resin, also it can be made by injection or extrusion from NdFeB alloy powder mixed with plastic. Higher Magnet Property: the magnet property of bonded NdFeB magnet is between that of sintered NdFeB and ferrite, and with good consistency and stability.

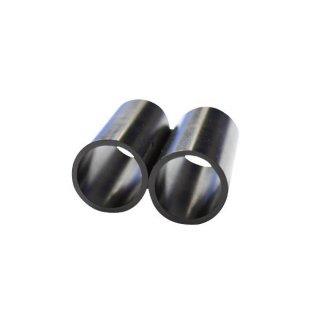

Coating: Black, Grey Epoxy; Prylene.

Magnetization: Multi-pole Magnetization

Performance:

Br T: 0.55-0.80

(BH)max k J/M3 (MGOe): 44-92 (5.5-11.5)

Tw 0C: 110-150

Product Tech: Powder--Belending--Granulation--Compaction--Curing--Refining--Coating--Magnetization--Packing

Features:

1. High precision;

2. Excellent magnetic properties;

3. Stable working temperature;

4. Good corrosion-resistance and nice surface.

The complete combination of injecting process and high-property rare-earth powder makes it possible to form easily the anisotropic (especially radial anisotrotropic)super-thin ring or block magnets in complex shapes.The products can be formed in a unit together with other components.This process provides high precision and high acceptable rate of products.

Usages:

1. The compression molding magnets, as for simple mould and high magnetic properties, are widely used in stepping motor, CD-ROM spindle motor, general motor, vibrating motor, pick-up, HDD spindle motor, and FDD spindle motor.

2. The injection molding magnets, as for complex mould, magnetic properties around 6 to 7 MGOe, and highly consistency, are widely used in electric expansion valve, air-condition motor etc,.

Company Profile

AOMAG specialized in the development and sales of permanent magnetic materials, magnetic circuit design, and magnetic components.

Our factory covers 10000 square meter, with employess 100 or more. We implement ISO 9000 idea in the factory over 7 years to keep steady quality level.

Strong technical R&D team, more than 30 material professionals & engineers, many well-trained, standard operation workers.