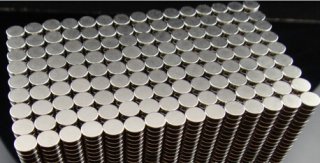

Product Information:

Material: Neodymium (Nd), Iron (Fe), and Boron (B)

Grade: N35-N52

Max working temperature: 80 Celsius degrees/176 degrees Fahrenheit

Size:Customized

Shape: Disc,Cylinder, Bar, Ring,Arc,Countersunk and up to customer’s request

Coating: Zn

Magnetization direction: Thickness Magnetized, Axially Magnetized,Diametrally Magnetized

Tolerance: ± 0.02mm

About Neodymium:

The third generation of rare earth permanent magnet NdFeB is the most powerful permanent magnet in modern magnets. It not only has the characteristics of high remanence, high coercivity, high magnetic energy product, high performance-to-price ratio, but also is easy to be processed into various sizes.

Neodymium magnet still offers the strongest magnetic power nowadays and has been widely served to vast kinds of application, include high-performance permanent motors, brushless DC motors, magnetic separators, magnetic resonance imaging (MRI), sensors, loudspeakers, consumer electronics, and green energy.

About Platings/Coatings:

Neodymium magnets are a composition of mostly Neodymium, Iron and Boron. If left exposed to the elements, the iron in the magnet will rust. To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated. There are a variety of options for coatings, but nickel is the most common and usually preferred. Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes our magnets much more durable than the more common single nickel plated magnets. Some other options for coating are zinc, tin, copper, epoxy, silver and gold.