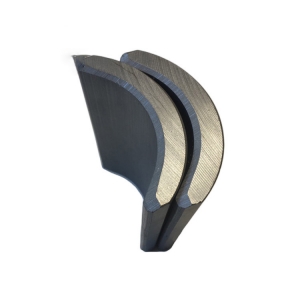

Alnico Magnet is composed primarily of Aluminum, Nickel, Cobalt, Copper and Iron. It have very good corrosion resistence and high max working temperature can reach 550deg.C. Although other materials offer greater energy and coercivity values,the high remanence and thermal stability of Alnico makes it the most cost effective material for certain applications, like generator, microphone lifeing, voltmeters and measuring instruments. It is widely applied in high stability fieled as aerospacce, military, automobiles and security system.

Advantages of Alnico Magnets

1.Cast Alnico offers a near net shape. Cast alnico can be produced to complex shapes with complex magnetic patterns.

2.Alnico Br as high as NdFeB at room temperature.

3.Can be used up to 450-550 degrees C.

4.Least variation in magnetic output with temperature change of any magnetic material.

5.Can be cast in very large sizes.

Company Profile

Fuzhou AOMAG Magnetics Co., Ltd.

As a professional magnets manufacturer, magnets supplier and OEM magnet exporter, AOMAG was established in 1996 and specialized in R&D, production and sales of rare earth magnets, permanent magnets, (licensed patent) neodymium magnets, Sintered NdFeB magnets (Neodymium-Ferrite-Boron) , strong magnets, Radial Ring magnets, bonded ndfeb magnets, ferrite magnets, alnico magnets, Smco magnets, rubber magnets, injection magnets, magnetic assemblies etc. Our factory has over 28 years' manufacturing experience in making magnets with different shapes, different coating, different magnetized direction, etc. We have complete production lines including raw material melting, crushing, powdering, pressing, sintering, machining, plating, quality-inspecting,etc. Our factory covers 10000 square meter, with employess 300 or more. We implement ISO 9000 idea in the factory over 7 years to keep steady quality level. We have over 19 years export experience so we can have good communication with customers and settle all kinds of export issues.