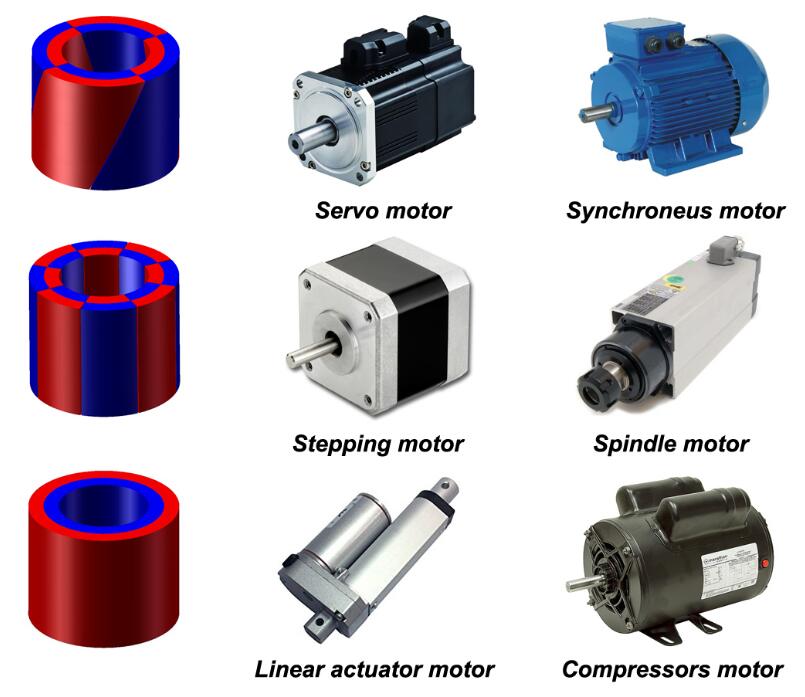

The advantages are significant:

• Motor assembly is made much easier; installation of one or more rings versus gluing arcs into place.

• Radial sintering assures no weak spots.

• Magnets are multi-poles thus the ring does not compromise the magnetic properties

• The radial orientation results in a super strong magnet by virtue of superior metallurgy developed specifically to BE radially oriented.

Technology:

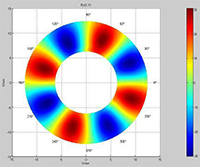

Hot pressing is a new method of producing sintered NdFeB magnets. This process consists of combining base powders, hot pressing the resulting material, and then baking or sintering the resulting ring to achieve a radially magnetized product. This new technology improves the magnetic flux which in turn provides better efficiency and performance.

|

|

|

Radial Dual-Pole Cylindrical Magnet |

High-Grade Radial Multi-Pole Ring |

|

|

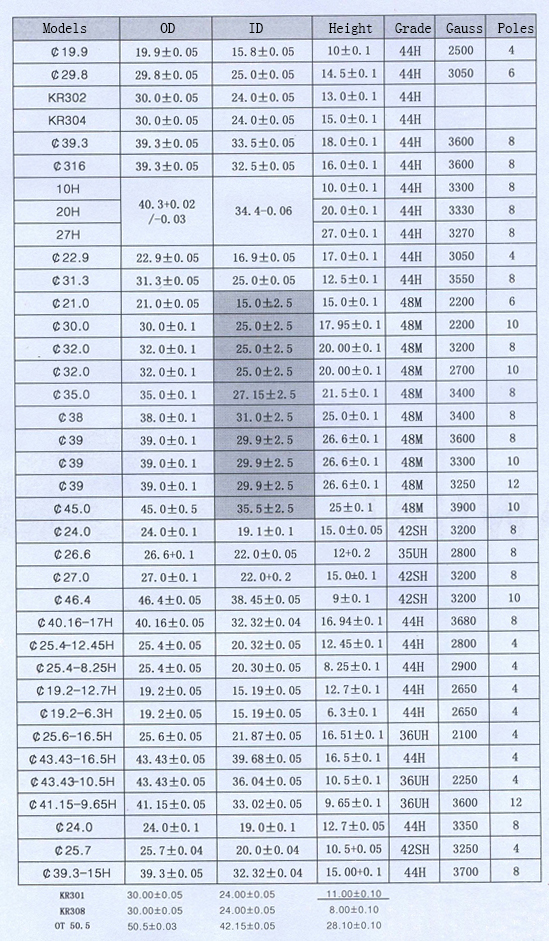

Available Dimension:

| O.D | I.D | Thickness(T) | Height(H) |

| <70mm | >15mm | 2<T<5mm | 25-50mm |

Below are the mould we have in stock. If you choose one of them, you will not pay for the mould fee. but you should have to pay for the Magnetic fixture fee.

You can use the mould as above and the ones with uni pole radial ring mgnets, meanwhile AOMAG have extral mould & magnetic fixture for Ndfeb Sintered multi poles ring magnets with diametrically magnetized as below:

D6*d3*20mm 4 poles

D14.5*d6.5*15mm 4 poles

D16*d12*12mm 4 poles

D16*d12*3mm 8 poles

D19*d14.97*20mm 8 poles

D19*d15.7*28mm 8 poles

D19*d5*20mm 4 poles

D20*d13*10mm 8 poles Skew 45degree

D21*d15*15mm 8 poles Skew 45degree

D21*d14*25mm

D26*d14*20mm 8 poles

D26*d18.5

D29*d24*25mm 8 poles

D29.2*d21.2*23mm

D29.2*d21.2*26mm

D29.2*d21.2*30.5mm

D29.2*d21.2*33mm

D32*d22*35mm

D35*d25*20mm 12 poles Skew 45degree

D35*d25*20mm 12 poles

D35*d25*20mm 20 poles

D35*d25*20mm 10 poles Skew 45degree

D35*d26*23.5mm

D35*d27*21.5mm

D39*d29*27.5mm

D39*d30*25.5mm 8poles

D40*d29*34mm

D42*d34*21mm

D16*d12*12mm 4 poles

D14.5*d6.5*15mm 4 poles

D16*d12*12mm 4 poles

*Special sizes may be produced depending on the grade, height-to-diameter ratio, and wall thickness.

Applications:

• Actuators |

Other Advantages:

• Geometric precision |

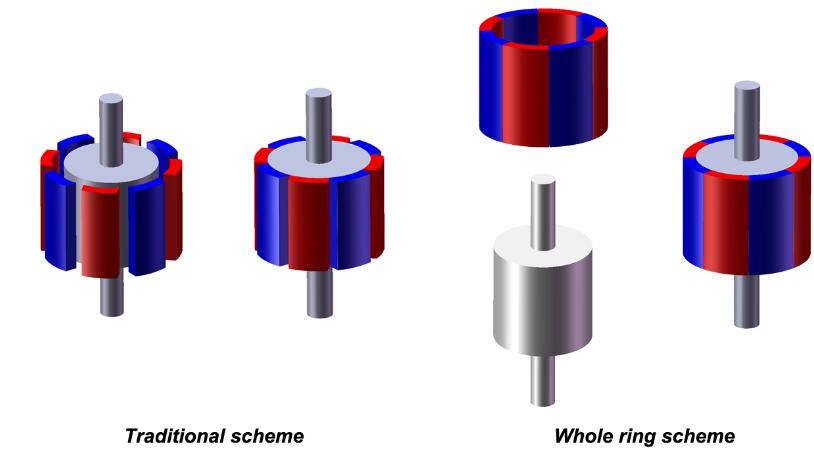

The advantages of radially oriented ring magnet

- The assembling process of motor assembly will be much easier than gluing arc segments magnets on a ring, also the assembling cost.

- The assembling accuracy of radially oriented ring magnet will be much higher than traditional multi-arc assemblies, then improve the dynamic balance of the motor.

- Improve the utilization rate of raw material.

- Modify the distribution of surface magnetic field, then motor powder will increase more than 15%.

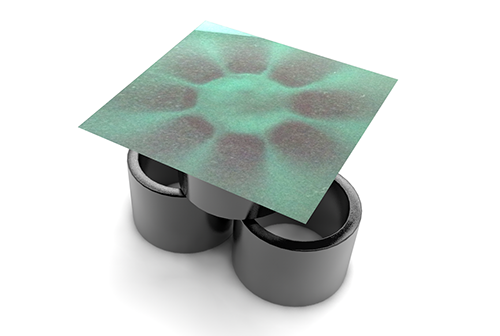

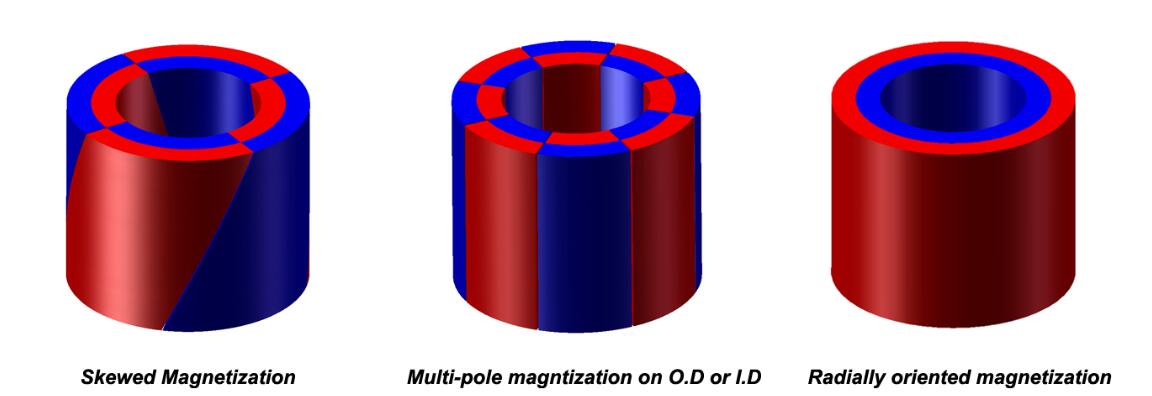

The magnetization patterns of radially oriented ring magnet

Applications of radially oriented ring magnet